|

|

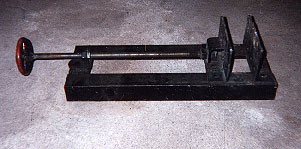

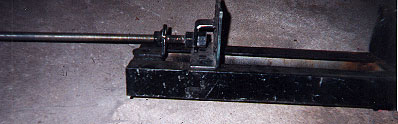

Building A Welding Vice from Scrap By: Bruce Bauerlein  WELDING VICE I needed a portable, but durable welding vice for my welding projects. I couldn't find what I was looking for, so I built one out of scrap material. BASE The base is made from 2"x 2"x 3/16" angle iron, which is welded together to form a rectangle which will be the base. Make sure that both ends of the slot opening, in the middle of the base, are the same distance apart. This will allow the movable jaw to slide freely on the base. FIXED JAW For the fixed jaw, I used 2"x 4"x 3/16" angles welded together. I welded the angles to one end of the base with the 4" part up and facing toward the inside of the base. SLIDING JAW The sliding jaw is made from the same size angles welded together. Place the sliding jaw on the base with the 4" ends facing each other. On the bottom of the sliding jaw, place two 1" square by 1/4" thick pieces of steel to act as guides, so the jaw doesn't jam on the base as it slides back and forth. The guides should have about a 1/8" space between the outside of the guide and the base frame. This will allow the jaw to slide on the guides. Weld a piece of 1"x 1/8" piece of steel, which is cut to extend onto the base side pieces about 1" on each side. This will hold the jaw onto the base . Weld this piece only to the guide pieces, so the jaw will slide on the base.  MOVING THE SLIDING JAW To move the jaw, I took a 1/4" by 2" wide piece of steel and drilled a 5/8" hole in it. I welded a 5/8" nut over one side of the hole. This is clamped to the end in the center of the base opposite the fixed jaw. Next, close the jaws and thread a 5/8 threaded rod through the hole. Then, place a piece of 2" x 2" x 3/16 angle iron about 2" wide on the outside of the sliding jaw, where the rod meets the jaw to form a box. Align the rod along the center of the base. Mark a spot on the box where the rod meets and drill a 5/8" hole for the rod. Then unclamp the piece with the nut. Thread a 5/8" nut onto the rod about 1" in. Then, place the rod through the new hole and put another 5/8" nut on the other side. Close the nuts together until there is a 1/16" space between each nut and the angle iron. This allows the rod to spin freely in the steel. Tack the nuts to the rod only. Place this assembly on the base with the angle iron end on the sliding jaw, again forming a box. The flat piece with the nut is clamped to the end of the base. Both pieces are then welded in place.  HANDLE For a handle, I welded an old round valve handle from a 4" gate valve onto the end of the threaded rod. The round handle is easy to turn while wearing heavy welding gloves. The finished product is a vice that is both durable and useful in holding various parts to be welded. Various views of the completed vice:    I didn't give any sizes of the material used to make the vice, as you can use any dimensions you want to suit your needs. |